1. Fast Production: Punching makes lots of parts quickly, perfect for big orders.

2. Precise and Consistent: Every part comes out the same, with accurate shapes and sizes.

3. Cost-Effective: Saves money on labor and material waste.

4. Works on Many Materials: Can be used on metal, plastic, and more.

5. Strong and Clean Parts: Creates durable parts with smooth edges, often needing no extra finishing.

6. Great for Large Quantities: Easy to scale up for mass production.

7. Saves Time: Combines multiple steps (like cutting and shaping) into one process.

8. Flexible: Easy to switch designs or tools for different parts.

9. Eco-Friendly: Reduces waste and uses energy efficiently.

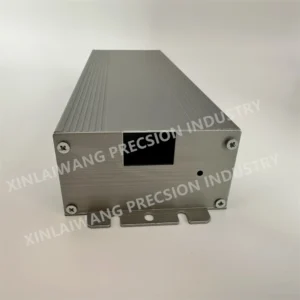

Shenzhen Xinlaiwang Precision Industry Co., Ltd. is a manufacturer specializing in manufacturing Precision punching die&molds, Punching shells and stamping parts.Include switching power supply Enclosures and casings, aluminum profile enclosurs, indoor mesh iron casings, display series aluminum enclosures, waterproof aluminum casings, radiators, Pressing parts and customized enclosures and other metal products.